Start Corrugated Carton Box Manufacturing Business – Business investment,profit and machinery details.

If you ever ordered something from online e-commerce stores such as Amazon and Flipkart, then there is a high probability that you came across a corrugated box. Well, according to “Wikipedia” definition, corrugated boxes, cardboard boxes, paper boxes, carton boxes are industrially prefabricated boxes which are primarily used for packaging goods and material.s All these boxes can also be recycled.

In this article, we will provide you with information on corrugated boxes manufacturing business, corrugated box manufacturing process, corrugated box making machine and finally how you can start the business.

Read : Business startup guide,how to make perfect plan

Market

Corrugated boxes are mostly used in businesses where packing of material is required. You can find their usage in industries such as pharmaceuticals, soaps, biscuits, cosmetics, tea & coffee, hosiery and shoe & footwear industry.

Around 80% of the industrial packaging is done using corrugated boxes as they are very light weight, easy to store and easy to dispose (i.e. recyclable) and as a result are environment friendly. Since they are cheap, they are widely used in various industries which requires packing of products. These boxes are heavily used by various e-commerce companies such as Amazon and Flipkart.

In this business, freight is a major factor as this product is cheap and is bulky and requires lots of space. Therefore, it is vital that your business location is very close to your customers.

The demand for corrugated boxes is very high and they are one of the fastest growing sector of the packaging market.

The benefits of corrugated cardboard packaging boxes over other packaging material are:

- Protects products;

- highly customizable;

- very cost-effective and sustainable;

- fully recyclable in nature etc.

Carton packaging boxes are available in different sizes and shapes and are usually rectangular and square in shape. They come in 3-ply, 5-ply and 7-ply etc.

To succeed in this business, it is important that you have knowledge and skill about the product and manufacturing process and are aware of various facets of the packaging industry. You can learn about this business by undergoing a course at the Indian Institute of Packaging. With regards to manufacturing, suppliers of these machines will be able to provide you with sufficient knowledge to operate and run this business.

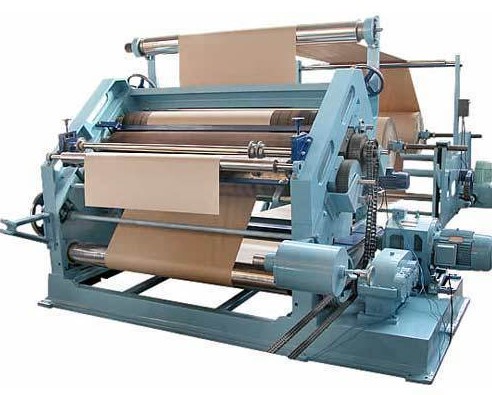

Machinery for corrugated box manufacturing

To run this business, you would need machinery which we have listed down below. You can buy these machinery from local manufacturers or through online B2B marketplaces such as Indiamart and Tradeindia.

1. Face Paper corrugation Machine

2. Board Cutters

3. Sheet Pasting Machine

4. Sheet Pressing Machine

5. Bar Rotary Cutting and Creasing Machine

6. Eccentric Slotted Machine

7. Stitching Machines.

Also, do not forget to check the customer’s reviews about the machine company before making a decision to purchase. You can negotiate the price of machines and also ensure that there is a warranty period available for the machines.

Raw Material for corrugated box manufacturing

As for raw materials, the main raw material would be craft or kraft paper. Other raw materials that are required for this business are yellow straw board, glue and stitching wire.

Legal Compliances

For this business, you will need to obtain trade license from the local authority and also procure factory license. You need to also get GST registration and also apply for consent for establishment and consent for operation both from the Pollution Control Board.

Corrugated Boxes Making Process

Let’s understand the process of making corrugated boxes.

Firstly wood chips are pulped through a Kraft process. The tree trunk is the raw material used in making the corrugated cardboard. Pine tree is the most suitable tree for the process of Kraft paper. It then goes through the sulfate process and gets broken down to fibrous pulp. The

Kraft rolls are then inserted into a corrugator machine.

Then the Kraft paper undergoes the heat, pressure and glue processing. It results in producing a continuous sheet of cardboard called box blanks. This cardboard is then cut into wide box blanks as per the template design. There are other processes which are also applied such as cutting, gluing and printing on boxes.

So this is how corrugated boxes are made.

Marketing

You should purchase high quality raw material. Ensure that the quality of your products is very high. Try to directly approach companies which require corrugated boxes for packing purposes. You can focus on industries such as pharma, food processing and e-commerce industries as we already mentioned previously that their requirement for these cardboard boxes is very high.

Also read : How to start medicine marketing business – step by step

You can list your business in popular B2B portals like Tradeindia and Indiamart, Just Dial as this could help you in generating leads for your business.

Don’t miss attending trade fairs and business expos which are focused on paper and packaging industries such as PackPlus, PackEx India and Paperex etc.

You should read publications related to this industry to keep yourself updated with what is happening in and around the packaging industry.

Conclusion

In conclusion, it is to be noted that the demand for corrugated boxes is very high and this is a growing sector in the packaging industry. However, this business requires a good sum of money to start, as the cost of the machinery is high and these are fixed costs to this business. Competition is also high in this business, due to the presence of many players in this market.

The profit margins in this business are not very high either but if you are able to make clients, have a USP and are able to build your brand, then it could be a business you can start.

We would suggest that, you learn this business first then go into this business as the business landscape is very competitive in packaging industry.

More business ideas & guide